Automotive electronics play a vital role in today’s vehicles by providing critical functions in engine management, safety systems, entertainment, navigation and communication. These specially designed electronics help to improve vehicle performance, fuel efficiency and safety.

All systems developed using automotive electronics are designed to withstand harsh environments. These components are expected to work without failure no matter what operating conditions the vehicle encounters. Because of this, the quality requirements for automotive electronic components are more rigorous than those for consumer goods.

The Automotive Electronics Council (AEC) is an organization that was founded in the 1990s by three of the United States’ major automobile manufactures – Chrysler, Ford, and General Motors. Its purpose was to establish global common part-qualification and quality-system standards for automotive electronic components.

To ensure that automotive electronic components were meeting the standards, the AEC Component Technical Committee was created. This committee is the standardization body responsible for establishing reliability and certification benchmarks for electronic components. Components that meet the specifications and standards set by the AEC Component Technical Committee are suitable for use in the harsh automotive environment without additional component-level qualification testing.

Note that AEC-Q200 was updated to version E in 2023 to include the ESD test for quartz crystals. The criteria for quartz crystals in AEC-Q200 are defined in Table 11.

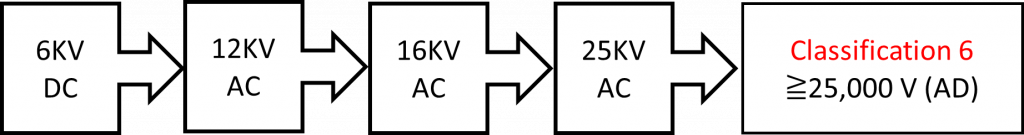

ESD Testing Procedure

DC=Direct Contact Discharge, AD = Air Discharge

Aker auto grade crystals have passed all testing requirements according to AEC-Q200 Rev-E and AEC-Q200-002 REV-B with classification level 6.

Aker offers a full range of AEC-Q200 Rev. E qualified crystals. With decades of experience supplying crystals to major automakers, you can trust Aker products to deliver reliable performance. When you need mission-critical timing components that meet stringent industry specs, look no further than Aker.

Contact Aker to discuss how our automotive-grade crystals can be used in your next design.

| Model | Dimensions (mm) | Model | Dimensions (mm) |

|---|---|---|---|

C7S Auto | 7.0×5.0x1.1 | C3E Auto | 3.2×2.5×0.75 |

| C6S Auto | 6.0×3.5×1.1 | C2E Auto | 2.5×2.0x0.65 |

| C5S Auto | 5.0×3.2×1.0 | C1E Auto | 2.0×1.6×0.5 |

| C4S Auto | 4.0×2.5×0.8 | C16 Auto | 1.6×1.2×0.4 |